Product Description

The Insulon® Low Pressure Insulated Hoses are vacuum jacketed hoses for gas or liquid transfer. These hoses utilize a proprietary insulation technology suitable for both cryogenic and high temperatures.

Applications

- Aerospace,

- Automotive,

- Cable & Wire Harnesses,

- Chemical Processing,

- Cleanroom Manufacturing,

- Cryogenic Fluid Transfer,

- Cryotherapy Devices,

- Food-Grade Applications,

- Fuel & Oil Lines.

Features

- Cleanroom-compatible materials (316L stainless steel),

- Compatible with cryogenic fluids including hydrogen, LN2, many others,

- Durable, reliable construction,

- Easy to install, clean and sterilize,

- Improve thermal energy efficiency,

- Low spring back reduces stress on connections and joints,

- Maintain safer external surface temperature,

- Minimize heat loss and conserve thermal energy,

- Naturally flame-retardant materials,

- Non-fibrous materials,

- Reduce condensation, dripping, and risk of mold,

- Reduce cryogenic material losses due to boil-off,

- Reduce risk of corrosion-under-insulation (CUI).

Specifications

- Thermal Range: -270°C to 900°C (-454°F to 1652°F),

- Jacket material: 316L Stainless Steel,

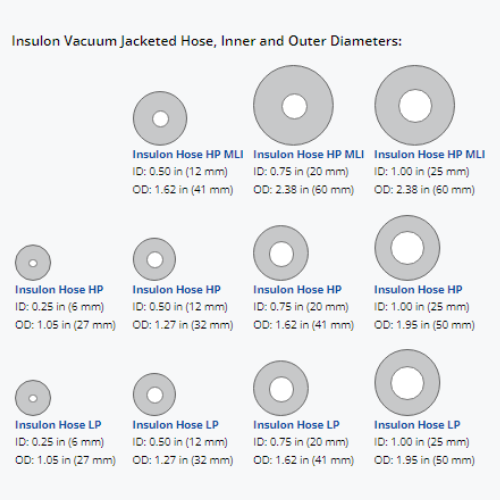

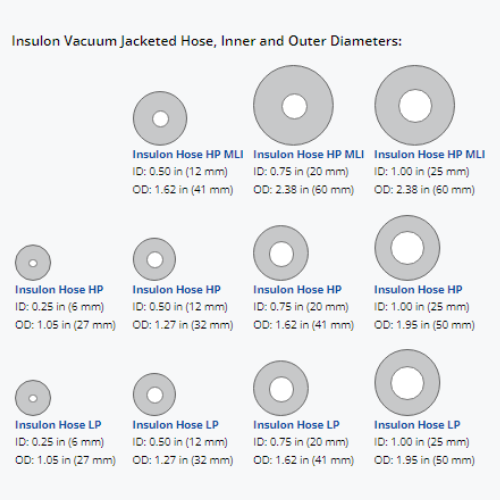

| Inner Diameter (in) |

1/4 |

1/2 |

3/4 |

1 |

| Outer Diameter (in) |

1.5 |

1.27 |

1.62 |

1.95 |

| Bend Radius Static (in.) |

2.65 |

3.33 |

4.1 |

5.08 |

| Bend Radius Dynamic (in.) |

6.58 |

7.5 |

10.2 |

11.75 |

| Maximum Allowable Working Pressure (MAWP) (PSI) |

72 |

43 |

| ID (in) |

1/4 |

1/2 |

3/4 |

1 |

| Tube Stub OD (in) |

0.250 |

.500 |

.750 |

1.00 |

| Tube Stub Thickness (in) |

0.035 |

0.049 |

| Min. Tube Stub ID (in) |

0.180 |

0.430 |

0.680 |

0.902 |

- Pressure tests are conducted at 1.5x MAWP according to NAHAD Corrugated Metal Hose Assembly Specification Guidelines, p. 33 (2005).

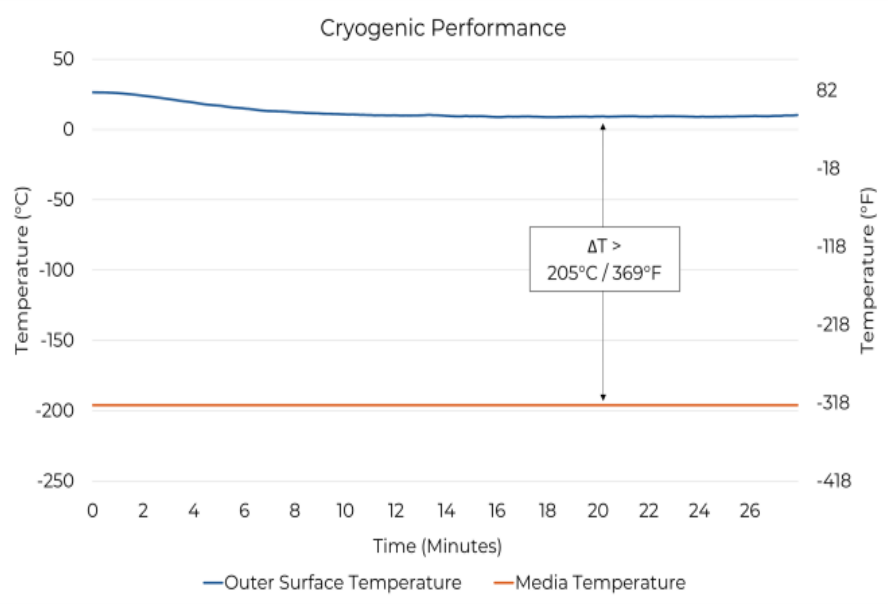

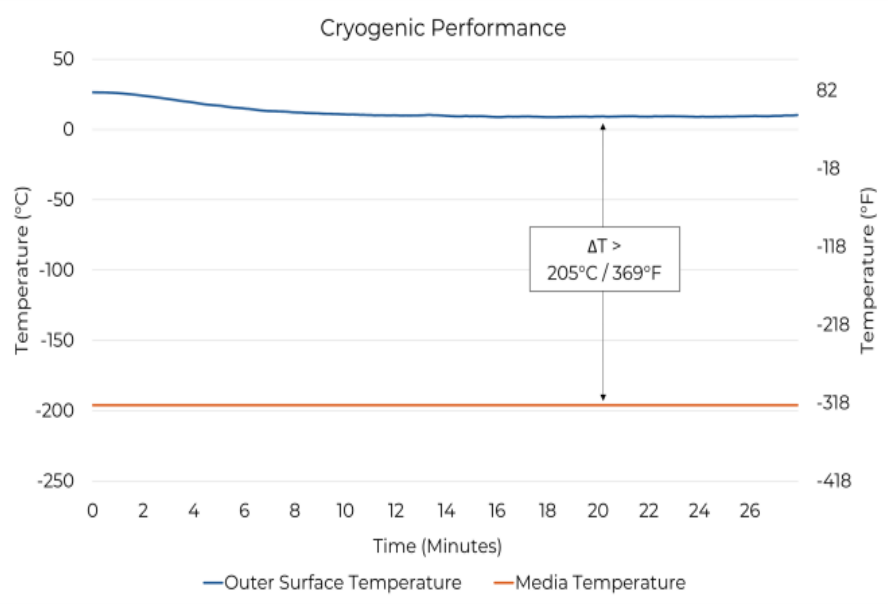

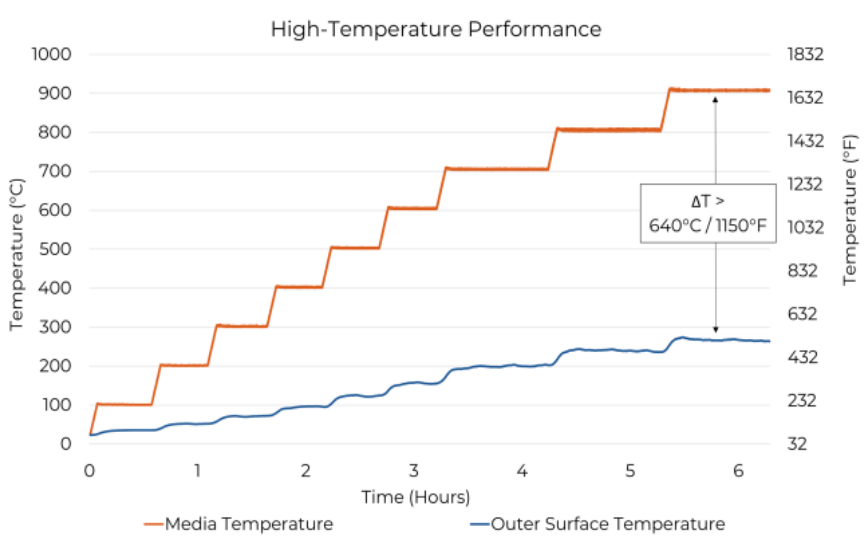

- Insulation “touch temperature” performance for 6ft Length Hose:

- Cryogenic Performance: For LN2 (at -196°C) the hose jacket temperature was over 9°C, for temperature difference (∆T) of >205°C (369°F) warmer.

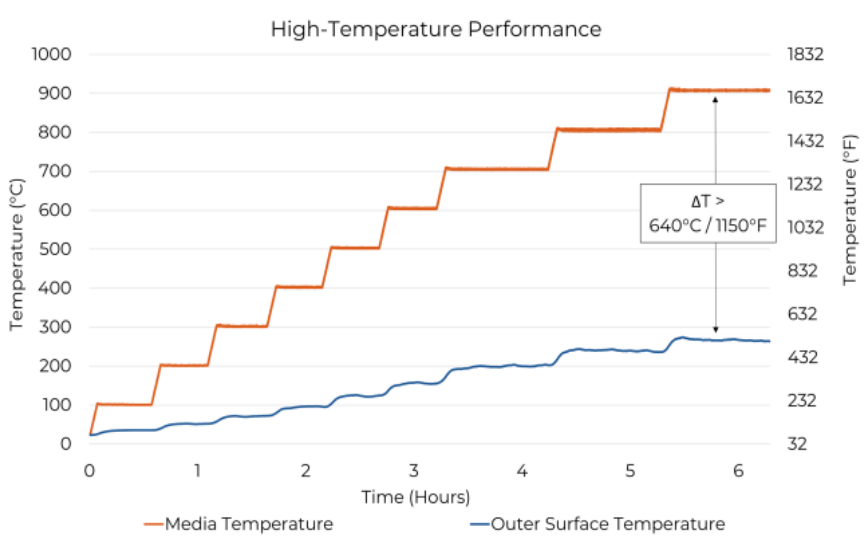

- High Temperature Performance: For hot air (at 900°C (1652°F) the hose jacket temperature maintained under 260°C (482°F), for temperature difference (∆T) of >205°C (369°F) cooler.

- This chart illustrates the difference between the media temperature (hot air) and the outer surface temperature (aka “touch temperature”). When the process media was 900°C (1652°F), the temperature difference was over 640°C (1150°F) at steady state.

- Insulation Reliability with Thermal Cycling:

- >20,000 cycles at 450°C without drop in insulation performance.

- Cycle was defined as a 3-minute ramp up during which the component reaches steady-state, followed by a 2-minute cool-down period. Ambient temperature was 23°C.

Optional Accessories

- Compression Union

- Brass by default unless Stainless Steel is requested.

- Compatible with all hose diameter options.

- Compression Male NPT

- Brass by default unless Stainless Steel is requested.

- Compatible with all hose diameter options.

- JIC 37 Degrees

- Compatible with all hose diameter options.

- CGA-295

- Compatible with

- Compatible with 1/2" hose diameter option only.

- Phase Separator

- Brass

- Compatible with 1/2" hose diameter option only.

- Contact CryoGearUSA for customized hose requests:

- Custom hose Lengths are available 2ft - 65ft.

- Custom configurations may have longer lead times.

---

US Dollar

US Dollar

AUD - AUSTRALIA

AUD - AUSTRALIA

JPY -JAPAN

JPY -JAPAN

ARA - ARGENTINA

ARA - ARGENTINA

ZAR - SOUTH AFRICA

ZAR - SOUTH AFRICA

TWD - TAIWAN

TWD - TAIWAN

CAD - CANADA

CAD - CANADA

MXN - MEXICO

MXN - MEXICO

BZD- BELIZE

BZD- BELIZE

CLP - CHILE

CLP - CHILE

BRL - BRAZIL

BRL - BRAZIL

PKR - PAKISTAN

PKR - PAKISTAN

INR - INDIA

INR - INDIA

UAH - UKRAINE

UAH - UKRAINE

GBP - GREAT BRITAIN

GBP - GREAT BRITAIN

RUB - RUSSIA

RUB - RUSSIA

CHF - SWITZERLAND

CHF - SWITZERLAND

CNY - CHINA

CNY - CHINA

ILS - ISRAEL

ILS - ISRAEL

EUR - EURO

EUR - EURO

SAR - SAUDI ARABIA

SAR - SAUDI ARABIA

SGD - SINGAPORE

SGD - SINGAPORE

THB - THAILAND

THB - THAILAND

MYR - MALAYSIA

MYR - MALAYSIA

PHP - PHILIPPINES

PHP - PHILIPPINES

IDR - INDONESIA

IDR - INDONESIA

NZD - NEW ZEALAND

NZD - NEW ZEALAND

SEK - SWEDEN

SEK - SWEDEN

DKK - DENMARK

DKK - DENMARK

NOK - NORWAY

NOK - NORWAY

TRY - TURKEY

TRY - TURKEY

KRW - SOUTH KOREAN REPUBLIC

KRW - SOUTH KOREAN REPUBLIC

PLN - POLAND

PLN - POLAND

CZK - CZECH REPUBLIC

CZK - CZECH REPUBLIC